Check Valve

Check Valve:

- Check valves are designed to prevent the reversal of flow in a piping system.

- These valves can be activated by the flowing material in the pipeline.

- The pressure of the fluid passing through the system opens the valve, while any reversal of flow will close the valve.

- Closure is accomplished by the weight of the check mechanism, by back pressure, by a spring, or by a combination of these means.

- Basic types of check valves are Swing check valve, Lift check valve, Ball check & Wafer check designs.

The type of disk will decide the type of valve. Most common types of Check valves are

- Swing Type.

i. Top Hinged

ii. Tilting disk

- Lift Type

i. Piston Type

ii. Ball type

The disc in a swing type valve is unguided as it fully opens or closes. This Valve operates when there is flow in the line and get fully closed when there is no flow. Turbulence and pressure drop in the valve is very low. Disk and seat designs can be of metal to metal or metal to composite.

The angle between the seat and the vertical plane is known as the seating angle and varies from 0 to 45 degrees. Usually, the seat angles are in the range of 5 to 7 degrees. Larger seat angles reduce the disc travel, resulting in quick closing, thus minimizing the possibility of water hammer. A vertical seat has a 0-degree angle.

The swing type valve allows full, unobstructed flow and automatically closes as pressure decreases. Usually installed in combination with gate valves because they provide relatively free flow combinations.

A basic swing type valve consists of a valve body, a bonnet, and a disk that is connected to a hinge.

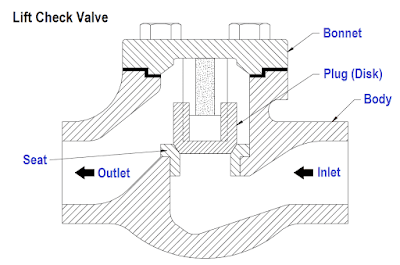

Lift Check Valve:

The lift check valve has a guided disk that is raised from the seat by upward flow pressure. Reversal of flow pushes the disk down against the seat, stopping back flow. Lift check have considerable resistance to flow, similar to that of globe valve. They are well suited for high pressure service.

Tilting Disc Check Valve:

The tilting disc type valve is designed to overcome some of the weaknesses of conventional swing type valves. The design of the tilting disk enables the valve to open fully and remain steady at lower flow rates and close quickly when the forwarding flow stop.

The dome-shaped disc floats in the flow and fluid flow on both the bottom and top of the disk surfaces. As the disk is spring-loaded, when forward flow pressure reduces, the spring force helps the valve to close fast. In the image above, you can see the flow from the valve.

Tilting Disc type Valve is available in wafer type and lug type design.

Advantages:

- They are self-actuated and require no external means to actuate the valve either to open or close. They are fast acting.

Disadvantages:

- Since all moving parts are enclosed, it is difficult to determine whether the valve is open or closed. Furthermore, the condition of internal parts cannot be assessed.

- Each type of check valve has limitations on its installation configurations.

- Valve disc can stick in open position.

Comments

Post a Comment